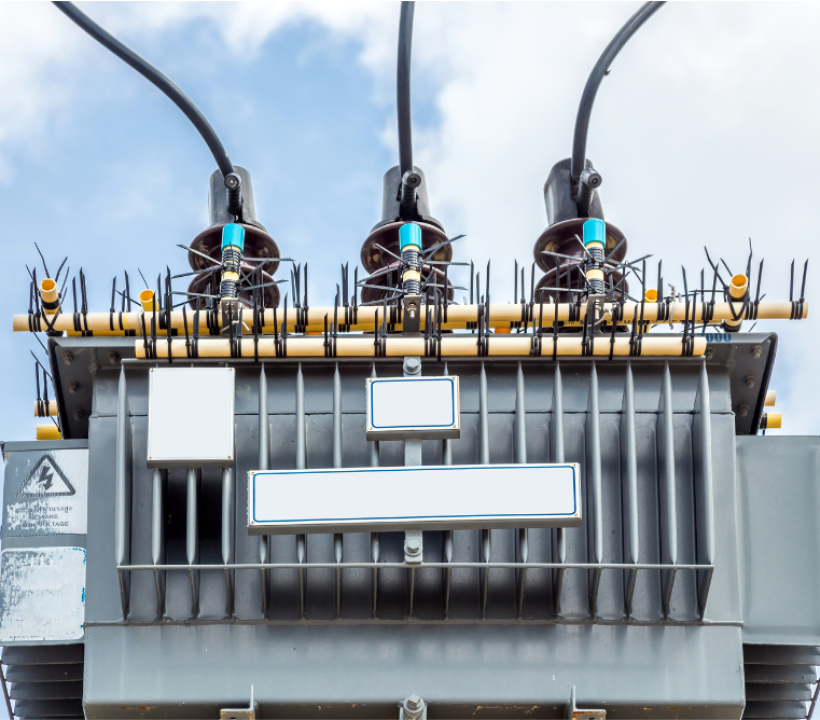

Transformers Complete Maintenance involves a comprehensive set of tasks aimed at preserving the optimal performance and reliability of transformers within electrical systems. This process includes various activities such as inspection, cleaning, testing, and repair to address potential issues and prevent unexpected failures. By adhering to a regular maintenance schedule, organizations can extend the lifespan of their transformers, minimize downtime, and ensure continuous operation of critical electrical infrastructure. Transformers Complete Maintenance is essential for mitigating risks, enhancing safety, and maximizing the efficiency of electrical systems.