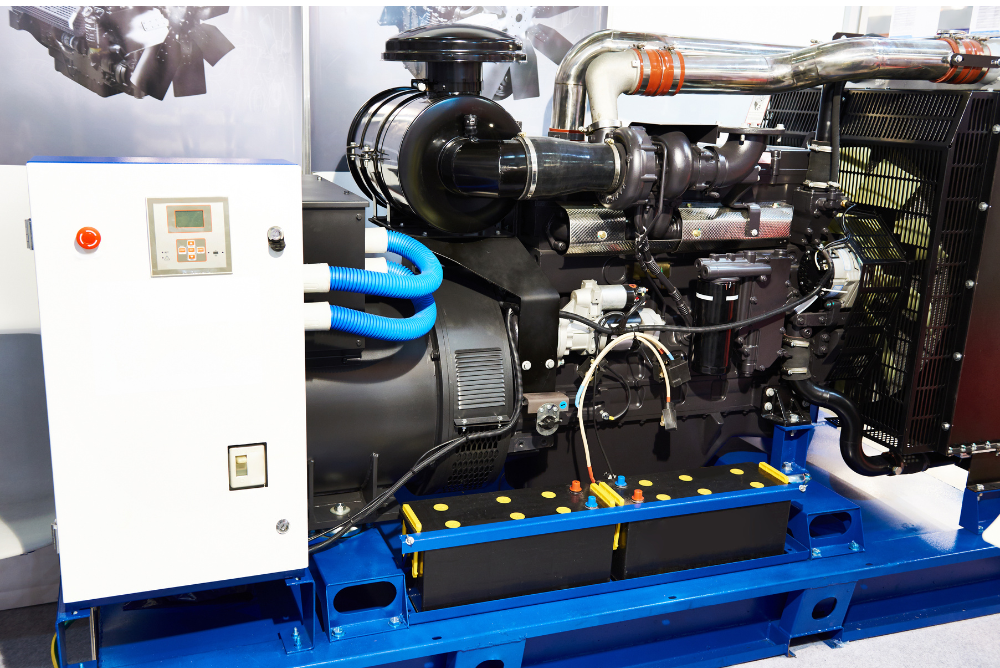

By investing in comprehensive generator maintenance services, businesses and organizations can minimize the risk of generator failures, ensure reliable backup power supply, and protect critical operations during power outages and emergencies. Regular maintenance also helps extend the lifespan of generators and optimize their performance, ultimately saving costs associated with repairs and replacements.